Los Angeles: Although supersonic travel bade goodbye over a decade ago with Concorde, a US-based start-up, Boom, is now developing a jetliner that will fly nearly 75 people — at the cost of a business class ticket — from New York to London in a little over three hours in 2023.

Boom supersonic airliner will aim to fly at Mach 2.2 (more than double the speed of sound) and cut flight times to half — 2.6 times faster than the current airlines.

Los Angeles-based Arrivo Corporation, that aims to commercialise the Hyperloop technology, is building fast corridors — starting from Denver, Colorado, in 2019 — that will drastically reduce travel time by road.

Brent Bushnell, who calls himself the nerdiest nerd on Earth, is creating “mad engineering projects” to teach kids science and robotics at his LA-based engineering and entertainment start-up Two Bit Circus, that offers tequila clouds, flame tanks and robot bartenders.

These start-ups have one thing in common: SOLIDWORKS and 3DEXPERIENCE solutions offered by the French 3D Experience major Dassault Systemes that are providing wings to their ideas.

Mike Jagemann, Head of XB-1 (XB-1 supersonic prototype is scheduled to fly this year) at Boom Supersonic, first learned SOLIDWORKS in college as part of a competitive aerospace team.

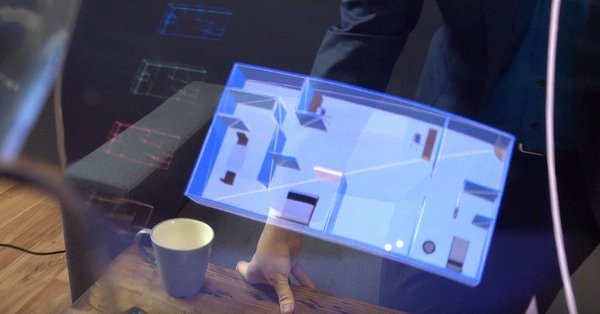

At one of the sessions, Jagemann explained that Boom is using SOLIDWORKS to design the entire aircraft — not just pieces of fuselage or the interior but the complete package, including computer-aided design (CAD), product data management (PDM), simulation and Augmented Reality (AR)/Virtual Reality (VR).

“Coming to the SOLIDWORKS conference is to connect with the best designers in the business who can help Boom take a giant leap. It’s a great place to grow your career,” Jagemann told the audience at one of the sessions.

Emerging start-ups are fast embracing SOLIDWORKS to design things that will change the future — from transportation to healthcare.

According to Ryan Kraft, an engineer from Arrivo, people who live in urban areas spend an average of 100 hours a year in traffic and the US loses billions of dollars as a result.

The company is using SOLIDWORKS and 3DEXPERIENCE solutions to design a high-speed super urban network to move people around cities.

The Arrivo network would have a magnetised track that parallels existing freeways. The system could support existing vehicles as well as cargo sleds and its own specially-designed vehicles.

According to Kraft, the company selected a minimum set of tools and processes to enable quick yet accurate manufacturing and testing, and will add in further toolsets and processes as they move to a production mindset.

“The company will spend the next 18 months to two years focusing on moving forward with technology, partners and customers… with doubling its engineering staff,” Kraft said.

British engineering company Gilo Industries is using SOLIDWORKS to design the “Mako” jetboard for water surfing.

According to its founder Gilo Cardoza, while the concept of a jetboard has been around since the 1930s, no one has ever done it really well.

“It needed to be lightweight, like a surfboard, and travel fast. The Mako goes 56 km per hour, has a 12-horsepower engine and goes from zero to 35 in 2.8 seconds. Using SOLIDWORKS, we went from art to finished product in just 12 months,” Cardoza told the gathering.

For Bushnell from Two Bit Circus, the best immersive experience is not a smartphone or a laptop — but real life.

“Engagement is the key to creative design. There’s no experience more immersive than real life and everyone in the SOLIDWORKS community has the tools and skills to create something innovative, engaging and memorable,” he noted.

When it comes to healthcare, Kyoungchul “KC” Kong, Professor of Mechanical Engineering at Sogang University in South Korea and CEO and founder of SG Robotics, has developed wearable robotics to help those in need of assistive technologies.

“Angelegs” is one such wearable robot system that helps paraplegic people walk.

According to Neri Oxman, a designer and professor at MIT’s Mediated Matter Lab, we are in the middle of the transition from the “age of the machines” to the “age of organisms”.

“In the ‘age of the machines’, 3D printing processes worked with voxels, but in the ‘age of organisms’, this information won’t be captured in binary systems but in systems based on genetic codes,” she noted, adding that the “Bio-digital” age will enable manufacturers to 3D-print organic materials.

“We all share a big dream and, most importantly, we have the knowledge, talent, character and determination to make things happen. Let’s make a better world for everyone,” reiterated Gian Paolo Bassi, SOLIDWORKS CEO.

— IANS