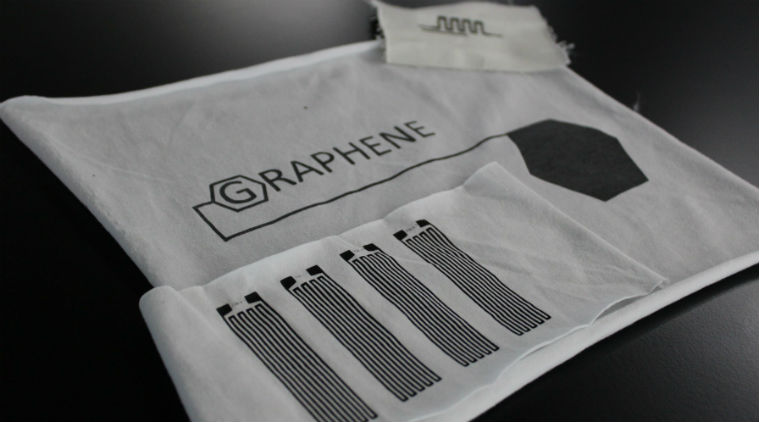

London: Scientists have developed a simple and cost-effective method to manufacture graphene-based wearable electronic-textiles on an industrial scale. Graphene is expected to be one of the most prominent materials in wearable e-textiles, however, there is no good way to manufacture them on an industrial scale, researchers said.

The new method could allow graphene e-textiles to be manufactured at commercial production rates of 150 meters per minute, they said. “To be able to produce graphene-based wearable e-textiles in scalable quantity at very high speed is a significant breakthrough for the rapidly growing wearables market,” said Nazmul Karim from The University of Manchester in the UK.

“Our simple and cost-effective way of producing multi-functional graphene textiles could easily be scaled up for many real-life applications, such as sportswear, military gear, and medical clothing,” said Karim. The researchers reversed the previous process of coating textiles with graphene-based materials, Phys.org reported.

Traditionally, the textiles are first coated with graphene oxide, and then the graphene oxide is reduced to its functional form of reduced graphene oxide. Instead, the researchers first reduced the graphene oxide in solution, and then coated the textiles with the reduced form.

By making coating the final step, it becomes possible to use a coating technique called padding, which is currently the most commonly used method of applying functional finishes to textiles in the textile industry. The researchers demonstrated that e-textiles made by a laboratory-scale pad-dry unit exhibited excellent electrical and mechanical characteristics.

PTI